Methods of Production

- Production is the transformation of resources (e.g. raw materials components and processes) into finished goods or services

- Goods are physical products, such as bicycles and T-shirts

- Services are non-physical items such as hairdressing, tourism and manicures

- Businesses can organise their production processes in a variety of ways

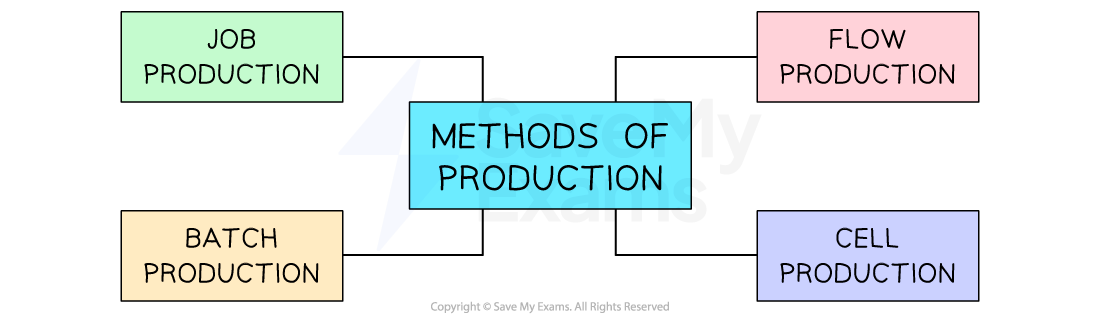

The main methods of production

- The method of production used by a business will depend upon a number of factors

- The level of output required to be produced

- The nature of the product

- Whether the product is standardised or customised

- The level of automation used in production

Assessing the Methods of Production

Method |

Explanation |

Advantages |

Disadvantages |

|

Job Production |

|

|

|

|

Flow Production |

|

|

|

|

Batch Production |

|

|

|

|

Cell Production |

|

|

|

Worked example

Blush Cosmetics uses batch production to make its range of soaps and bath bombs, with a variety of unique ingredients and scents. The business sells its products in its own high street store and online and has recently started supplying its products in small quantities to a chain of exclusive hotels.

Explain one likely reason why Blush Cosmetics chooses to use batch production. (4)

Step 1 - Identify a reason for the business to use batch production

One reason for Blush Cosmetics to use batch production is that it allows groups of products with varied ingredients to be manufactured. (1 mark)

Step 2 - Include a reference to the business scenario

Blush cosmetics sells a range of bath bombs and soaps which have different fragrances, colours and ingredients. (1 mark)

Step 3 - Develop the reason using a connective

Blush Cosmetics needs to produce significant quantities of output to meet increasing demand and batch production, as well as providing the opportunity to change ingredients between batches (1 mark), can allow quite large quantities to be produced for their high street and online stores (1 mark).

Or

Using batch production can allow Blush Cosmetics to produce smaller quantities of unique products for the exclusive hotel customer (1 mark), meeting their specific needs (1 mark).

Exam Tip

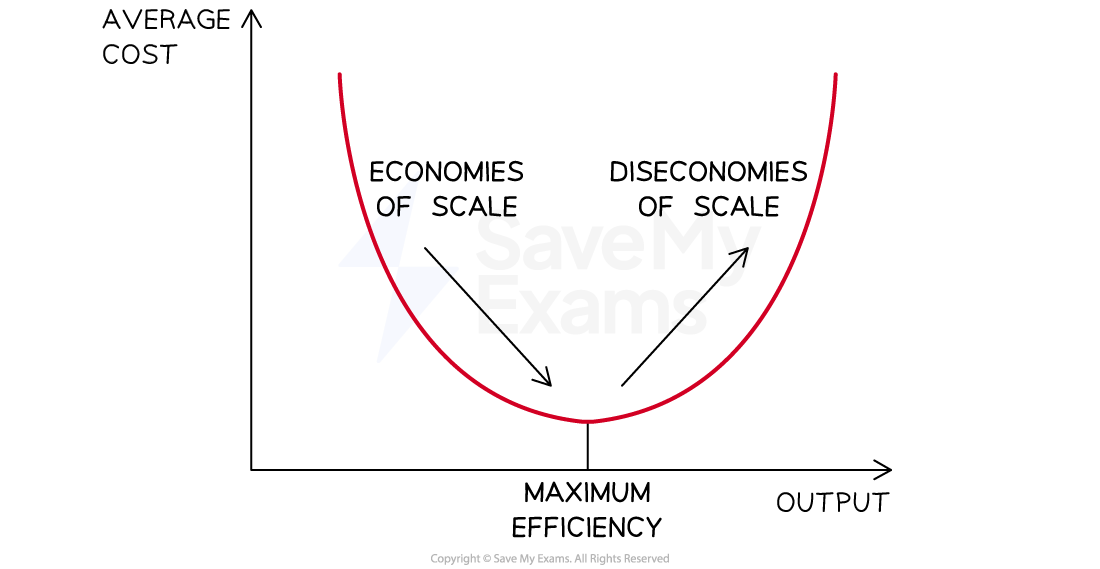

Carefully consider the needs of the customers to which a business sells when recommending a suitable method of production. Where the selling price is a key driver of consumer demand, flow production (where unit costs are minimised) is likely to be very suitable. Where demand is driven by quality or where customisation is required, job or batch production are likely to be better choices.