Efficiency in Production (AQA GCSE Business)

Revision Note

Author

Lisa EadesExpertise

Business Content Creator

An Introduction to Lean Production

Lean production involves the minimisation of the resources used in production

Less time is required as the production process is organised in the most efficient way

Fewer materials are used as there is a focus on waste reduction

Less labour is used as lean production is typically capital intensive

Little space is required for production and storage

A small number of trusted suppliers work closely with the business

Efficiency gains through the use of lean production are likely to lead to a competitive advantage

Lower unit costs are achieved due to minimal waste, so prices may be lower than those offered by competitors

Better quality of output is likely as a result of supplier reliability and carefully managed production processes

However, lean production requires very careful coordination

Suppliers must be capable of responding very quickly to stock requests

Workers need to be motivated and flexible, capable of switching between a variety of tasks and constantly alert to changes they can make to improve efficiency

Managers need to maintain excellent relationships with workers to avoid disruptions to production

Equipment and machinery need to be well-maintained

Quality issues need to be identified and corrected swiftly, requiring effective quality assurance processes to be implemented and monitored constantly

All workers have a responsibility for quality, so ongoing training is vital

Elements of Lean Production

Lean production uses strategies such as just in time production and Kaizen

Just in time production

Just in time production means that the business only manufactures products when a customer confirms an order for them

This reduces the need for storage, as stock is only ordered to arrive when needed and products only made when there is demand

Kaizen

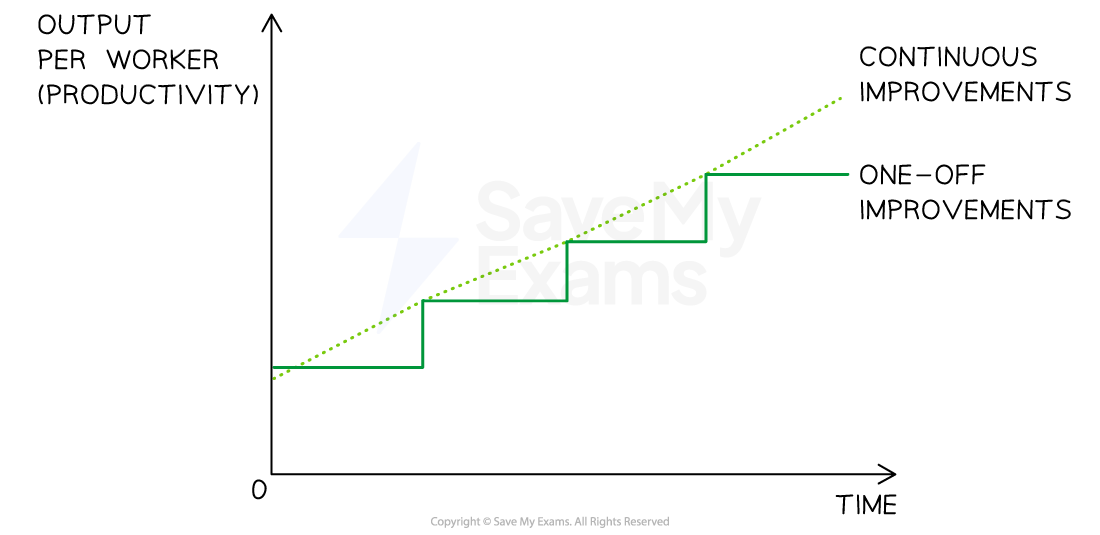

Kaizen involves taking continuous steps to improve productivity

Changes are small and ongoing, rather than significant one-off changes

It requires a long-term management commitment to change as well as flexible workers fully engaged in continuous improvement

Diagram: How Kaizen Works

Kaizen Versus One-off Improvements

Elements of Kaizen commonly include:

Zero defects in manufacturing

Capital-intensive methods using advanced machinery

High levels of cooperation between workers and management

Exam Tip

A common misconception is that lean production is an alternative to job or flow production. Lean production is not a production method, but rather a whole-business philosophy that is absolutely focused on minimising waste at every level.

You've read 0 of your 0 free revision notes

Get unlimited access

to absolutely everything:

- Downloadable PDFs

- Unlimited Revision Notes

- Topic Questions

- Past Papers

- Model Answers

- Videos (Maths and Science)

Did this page help you?